3003 and 5052 are both

aluminum alloys that are widely used in various industries due to their

excellent properties. In this article, we will compare the composition and

properties of both alloys.

Composition: 3003 is an

aluminum-manganese alloy that contains about 1-1.5% manganese, while 5052 is an

aluminum-magnesium alloy that contains about 2.2-2.8% magnesium. Additionally,

3003 contains a small amount of copper (0.05-0.20%), while 5052 contains chromium

(0.15-0.35%) and a smaller amount of copper (0.10% maximum).

|

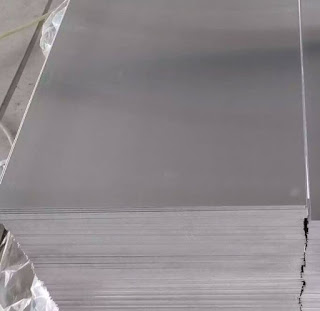

| 3003 Aluminum Plates |

Properties:

1. Corrosion

Resistance: Both 3003 and 5052 have excellent corrosion resistance, making them

suitable for use in harsh environments. However, 5052 has better resistance to

saltwater and industrial chemical environments.

2. Strength:

5052 has a higher strength-to-weight ratio than 3003, making it suitable for

use in structural applications where strength is important.

3. Formability:

Both alloys have good formability, but 3003 is easier to form and shape due to

its higher ductility.

4. Weldability:

Both alloys have good weldability, but 5052 is easier to weld due to its higher

magnesium content.

5. Machinability:

Both alloys have good machinability, but 3003 is easier to machine due to its

lower strength and hardness.

6. Surface

Finish: Both alloys have excellent surface finishes, allowing them to be easily

polished, anodized, or painted.

Applications:

3003 is commonly used in

low-load applications that require high plasticity and good weldability, such

as kitchen utensils, food and chemical product processing and storage devices,

tanks, and tanks for transporting liquid products, various pressure vessels and

pipes processed with thin plates, general utensils, heat sinks, cosmetic

plates, photocopier rollers, and ship materials.

5052 is commonly used in

marine and transportation applications such as boats, ships, and aircraft, as

well as structural and architectural applications such as building facades,

roofs, and panels. It is also used in chemical and food processing equipment,

sheet metal work, electronic components and appliances, and pressure vessels

and tanks.

In conclusion, while both

3003 and 5052 aluminum alloys offer excellent properties, they have some

differences in composition, properties, and applications. 3003 is easier to form

and is commonly used in low-load applications, while 5052 is stronger and more

commonly used in structural and marine applications.

Comments :

0 Comments to “Comparing the Composition, Properties, and Applications of Aluminum Alloys 3003 and 5052”

Post a Comment

If you have any questions, concerns, or feedback about our website, our team is always here to assist you.